+86-0580-8052088

+86-13505800981

No. 20, Liguan Road, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China

1. Several important parameters of the screw 1, screw […]

1. Several important parameters of the screw

1, screw diameter (D)

A. Related to the required injection volume:

Injection volume=1/4*π*D2*S (injection stroke)*0.85;

B. Generally speaking, the screw diameter D is inversely proportional to the maximum injection pressure and directly proportional to the plasticizing ability.

2, transport section

A. As the transportation, pushing and preheating of plastic, it should be ensured that the preheating reaches the melting point;

B, crystalline plastics should be long (such as POM, PA), followed by amorphous materials (such as PS, PU, ABS), and the shortest heat sensitivity (such as PVC).

3, tightening section

A. Responsible for the mixing, compression and pressurization of plastics. The materials that have passed through this section are almost completely melted, but they do not have to be uniformly mixed;

B. In this area, the plastic gradually melts, and the volume of the screw groove must be reduced accordingly to correspond to the slight volume decrease of the plastic, otherwise the material is not compacted, the heat transfer is slow, and the exhaust is poor;

c. Generally, it accounts for more than 25% of the operating length of the screw, but the shrinking section of the nylon (crystalline material) screw accounts for about 15% of the operating length of the screw, and the plastic screw with high viscosity, fire resistance, low conductivity, high additives, etc., accounts for 40% \'50% screw working length, PVC screw can account for 100% screw working length to prevent severe shear heat.

4, measurement section

A. Generally accounts for 20\'25% of the operating length of the screw to ensure that all plastics are melted and the temperature is uniform, and the mixing is uniform;

B. Long metering section will have better mixing effect, too long will make the melt stay too long and cause thermal differentiation, too short will make temperature uneven

C, PVC and other heat-sensitive plastics should not stay too long to prevent thermal differentiation. A shorter metering section or no metering section can be used.

5. Feeding screw groove depth, measuring screw groove depth

a. The deeper the feed groove depth, the greater the delivery capacity, but the strength of the screw must be considered. The shallower the metering groove depth, the higher the plasticizing heat and mixing function index, but the shallow metering groove depth means shearing Thermal addition, self-generated heat addition, too high temperature rise, discoloration or scorching of the plastic, which is particularly unfavorable for heat-sensitive plastics;

B. Measuring screw groove depth=KD=(0.03\'0.07)*D, if D increases, select a small value for K.

2. Important factors affecting the quality of plasticization

The main factors that affect the quality of plasticization are: length to diameter ratio, compression ratio, back pressure, screw speed, barrel heating temperature, etc.

1. Length-diameter ratio: the ratio of the useful working length of the screw to the screw diameter.

A. A large aspect ratio will make it easier to eat evenly;

B. For plastics with better thermal stability, a longer screw can be used to improve the mixing performance without scorching, and for plastics with poor thermal stability, a shorter screw can be used or the end of the screw without threads. Considering the characteristics of plastics, the general flow length ratio is as follows: thermosetting is 14\'16, heat sensitivity such as rigid PVC, high-viscosity PU is 17\'18, general plastic is 18\'22, and high temperature stable plastics such as PC and POM are 22\'24.

2. Shrinkage ratio: It is the ratio of the depth of the last groove of the feed section to the depth of the first groove of the metering section.

A. Consider the effects of material shrinkage, filling degree, backflow, etc., products should be dense, heat transfer and exhaust;

b. Appropriate compression ratio can add the density of plastic to make the molecules and molecules more tightly bound, which helps to reduce the absorption of air, reduces the temperature rise due to pressure, and affects the difference in output, improper compression Than will damage the physical properties of the plastic;

C. The higher the shrinkage ratio, the higher the temperature rise that occurs during the plasticization of the plastic in the barrel, the better the mixing uniformity of the plastic during the plasticization, and the relative output is greatly reduced.

D. High shrinkage ratio is suitable for non-melting plastics, especially plastics with low melting viscosity and heat stability; low shrinking ratio is suitable for fusible plastics, especially high melting viscosity, heat-sensitive plastics.

3, back pressure

A. Adding back pressure can increase the work done by the screw on the molten resin, eliminate unmelted plastic particles, and add the density and uniformity of the material in the tube;

B. Back pressure is used to increase the barrel temperature, its effect is the most obvious;

C. If the back pressure is too large, it is easy to differentiate the plastics with higher heat sensitivity, and the salivation phenomenon may occur to the low-viscosity plastics. If the back pressure is too small, the injection molded products may have bubbles.

4, screw speed

A. The rolling speed of the screw directly affects the shear of the plastic in the spiral groove;

B. The small screw groove is shallow and absorbs the heat source quickly, which can promote the softening of the plastic at the moment of the shrinking period, and the conflict between the screw and the barrel wall is relatively low, suitable for high-speed rotation, and plasticizing ability is added;

C. Large screws are not suitable for rapid rotation to prevent uneven plasticization and excessive conflict heat;

D. For plastics with high heat sensitivity, if the screw speed is too high, the plastics will be easily differentiated;

E. Generally, each standard screw has a certain speed scale, the general speed is 100\'150rpm; if it is too low, the plastic cannot be melted, and if it is too high, the plastic will be scorched.

5, electric heating temperature setting

A. Melt the chilled plastic that stays in the barrel and screw to facilitate the rolling of the screw, and supply the plastic to obtain part of the heat required for melting;

B. Set 5\'10℃ lower than melt temperature (partly supplied by conflicting heat energy);

C. The adjustment of nozzle temperature can also be used to control salivation, condensate (plug nozzle), wire drawing and other issues;

D. General temperature control of crystalline plastics;

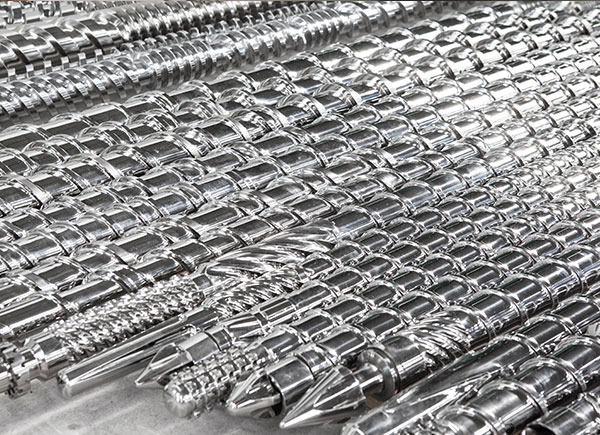

3. Selection criteria for plasticizing material pipe group and planning of rubber head components

(1) Consider the key points: transport section, tightening section, metering section, ratio of three sections, shrinking ratio, groove depth of metering section, ratio of length to diameter, number of threads.

(2) Selection criteria

A. If you want to have a better mixing effect, choose a plan with a large aspect ratio, a large number of threads, a large shrinkage ratio, and a shallow groove in the metering section, such as: PA, PE, PP, POM;

b. If you want to prevent shearing and overheating, choose a plan with a small length to diameter ratio, a small number of threads, a compact length, a small compaction ratio, and a deeper groove in the metering section, such as: PC, PMMA, rigid PVC, and glass fiber Or fireproof material;

C. For those who want a high plasticization rate, choose a plan with a smaller shrinkage and a deeper groove in the metering section.

(3) Planning of plastic head components

A good check valve should have:

A, the ability to quickly stop reverse speed;

B. Ability to completely stop reversal to keep the plastic backflow phenomenon to a minimum;

C. The material flow is smooth, and there is no dead angle to prevent partial shearing heat, which may cause plastic deterioration;

D, wear resistance, corrosion resistance;

E, suitable for a variety of plastic applications

https://www.txscrew.com/

Copyright:Zhoushan Tianxiang Screw Factory

China Conical Twin Screws ManufacturersTechnical Support: HWAQ