+86-0580-8052088

+86-13505800981

No. 20, Liguan Road, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China

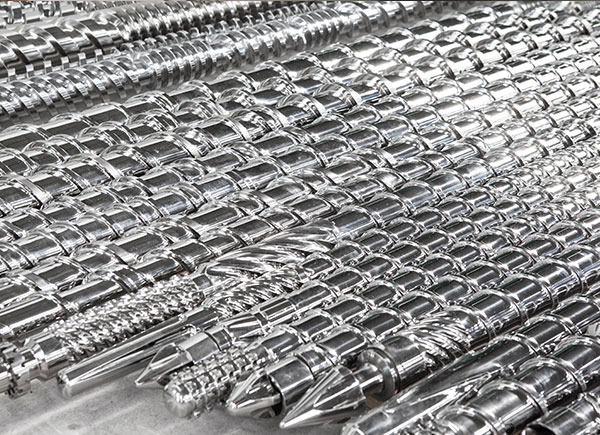

PC special screw: for PC and other high viscosity plast […]

PC special screw: for PC and other high viscosity plastics, it has less shearing heat, acid corrosion resistance, medium and small diameter, good molding effect of PC, PP-R, flame retardant ABS, etc. It can also be used for general plastics and PMMA products. The color mixing effect is poor. If the color powder is added in the plastic, it is necessary to customize the screw with enhanced color mixing.

PA special screw: in view of PA low viscosity, difficult to color, fast melting speed, good self-lubricating characteristics, the screw has good color mixing effect, stable feed quantity and good exhaust effect. Center diameter. The effect of molding low viscosity base plastics such as PA, PP and LCP is good. It can also be molded into general plastics. The plastics with high viscosity and poor thermal stability, such as PC, PMMA flame retardant ABS, are not applicable (high temperature and differentiation in the middle section)

PMMA special screw: according to the requirements of PMMA Tongming products, good plasticizing effect, low differentiation rate, good plasticization, low shear heat and good color mixing. When the center diameter molding PMMA, PP-R, PC, ABS and other color powder are added, the effect is good, such as plastic with flame retardant, screw need chrome plating.

UPVC special screw: for the characteristics of high viscosity, easy differentiation, strong corrosion and good plasticization of PVC pipe joint. The screw has good plasticization, less shearing heat and acid corrosion resistance. Because there is no apron, it can not be used for low viscosity plastics and injection speed and pressure classification more accurate products. In addition, because of the need for heat dissipation and cooling, the timing cylinder (melt cartridge) of UPVC products should use forced air cooling measures and screw cooperation.

Pet special screw: according to the characteristics of pet low viscosity, high specific heat capacity, easy to stick material and PET bottle blank requiring fast plasticization and even plasticization, the screw has good plasticization, high stability, non sticking material, fast melting speed, and high yield of finished product when blowing the preform. Large diameter, can also be used to shape general plastics.

PBT special screw: for the simple differentiation of PBT, sensitive to pressure and the need to increase glass fiber characteristics, screw pressure stability, and the use of double alloy to improve wear resistance.

Acid screw assembly: in view of the strong corrosive properties of CP, Ca and other acid plastics, special plans have been made in the structure and surface treatment of screw, melt cartridge and other plasticized parts. The screw assembly can resist corrosion.

Copyright:Zhoushan Tianxiang Screw Factory

China Conical Twin Screws ManufacturersTechnical Support: HWAQ