+86-0580-8052088

+86-13505800981

No. 20, Liguan Road, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China

Screw barrel data 1. Requirements for raw materials Acc […]

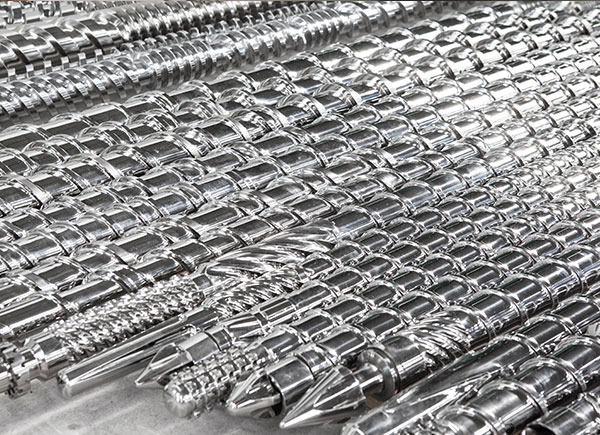

Screw barrel data

1. Requirements for raw materials

According to the extrusion process, the screw works under high temperature, certain corrosion, severe wear and high torque

1) High temperature resistance, no deformation under high temperature;

2) Wear resistance and long service life;

3) It is corrosion resistant and the material is corrosive;

4) High strength, can accept large torque, high speed;

5) It has excellent cutting function;

6) After heat treatment, the residual stress is small and the thermal deformation is small.

2. Common data and heat treatment

Now commonly used screw data are 45 steel, 40Cr, ammoniated steel, 38CrMoAl, etc.

1) No. 45 steel is cheap and has good processing function, but its wear resistance, corrosion resistance and aging resistance are poor.

Heat treatment: quenching and tempering hb220-270, high frequency quenching hrc45-48

2) The function of 40Cr is better than that of 45 steel, but a layer of chromium is often needed to improve its corrosion and wear resistance. However, the chromium plating layer is required to be higher. If the coating is too thin, it is easy to wear. If it is too thick, it is easy to fall off. After falling off, it will accelerate the corrosion. Now it is less used.

Heat treatment: quenching and tempering hb220-270, hard chromium plating HRC > 55

3) Nitriding steel and 38CrMoAl have excellent comprehensive functions and are widely used. Generally, the nitrided layer is 0.4-0.6 mm. But this kind of data has low ability to resist hydrogen chloride corrosion and high price.

Heat treatment: quenching and tempering hb220-270, nitriding HRC > 65

In foreign countries, titanium carbide coating is used to improve the corrosion resistance of screw surface, but it is reported that its wear resistance is not good enough. In recent years, foreign countries have adopted a series of methods to improve the wear resistance and corrosion resistance of screw. One way is to choose high wear and corrosion resistant alloy steel. Such as 34cralni, 31crmo12, etc. There are also ways to spray Xaloy alloy on the surface of the screw. The Xaloy alloy has high wear resistance and corrosion resistance (see barrel section for details).

Strength calculation of screw

When the screw is matched with the main shaft of the reducer with a long cylindrical surface, the screw can be used as a cantilever beam with one end fixed. The stress state of screw in extrusion process can be simplified as follows:

1. Stress condition of screw

1) Self weight g;

2) Torque M required to overcome material resistance;

3) The axial force P produced by material pressure.

Generally, the screw is worn for a long time, and the gap between the screw and the barrel is too large to extrude normally. However, due to improper planning or operation, the working stress exceeds the strength limit and is damaged, for example. Therefore, the screw should also meet certain strength requirements.

4) The risk section of screw is generally at the minimum thread root diameter of feeding section.

According to the data mechanics, for the plastic data, the composite stress is calculated by the third strength theory

2. Intensity accounting

3. Other conditions

1) As for the floating connection between the screw tail and the main shaft of the reducer, because the screw floats in the barrel, the bending stress caused by the weight of the screw is equal to zero, so it is only calculated according to the screw compression stress and shear stress.

2) Because the bending stress caused by the dead weight of the screw is very small (the material is filled around the screw), even in the former case, it can be omitted, so the two methods are actually the same.

3) There are also pure torsion to budget the diameter of the screw.

Copyright:Zhoushan Tianxiang Screw Factory

China Conical Twin Screws ManufacturersTechnical Support: HWAQ