+86-0580-8052088

+86-13505800981

No. 20, Liguan Road, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China

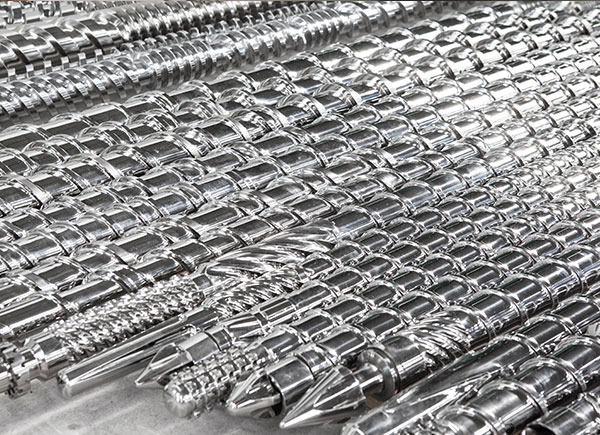

The screw is an important part of the injection molding […]

The screw is an important part of the injection molding machine. Its function is to transport, compact, melt, stir and apply pressure to plastics. All of these are accomplished by the rotation of the screw in the barrel. When the screw rotates, the plastic will generate friction and mutual movement on the inner wall of the barrel, the bottom surface of the screw groove, the screw edge advancement surface, and the plastic and the plastic. The advancement of plastic is the result of this combination of movements, and the heat generated by friction is also absorbed to increase the temperature of the plastic and melt the plastic. The design structure of the screw will directly affect the extent of these effects. The editor will explain the process of the screw for you below:

The screw material is selected from high-quality 38CrMoAla, high-quality SACM645, high-quality SKD11; high-quality SKD61; high-quality 9Cr18MoV (high-quality stainless steel); CW6Mo5Cr4V2 (high-speed tool steel); HPT (fully hardened powder alloy tool steel)

Screw technical requirements:

Nitride layer depth: 0.50-0.70mm

The surface hardness of the screw barrel is not less than HV950°

Screw brittleness: ≤ two

Screw straightness: 0.015mm/m

The roughness of the screw working surface is not less than Ra0.4um

The screw has high strength,

High temperature and high pressure

The surface is corrosion-resistant and wear-resistant.

To improve the wear resistance and corrosion resistance of the screw surface, the screw surface is respectively nitrided, fully hardened, alloy sprayed, hard chromium plated or titanium plated.

Copyright:Zhoushan Tianxiang Screw Factory

China Conical Twin Screws ManufacturersTechnical Support: HWAQ