+86-0580-8052088

+86-13505800981

No. 20, Liguan Road, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China

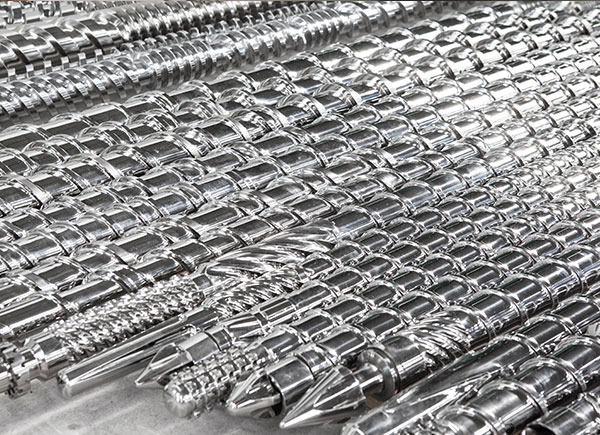

High-speed, high-yield extruder high-speed, high-yield, […]

High-speed, high-yield extruder high-speed, high-yield, can enable investors to obtain greater output and high returns with a lower investment. However, the high speed of the extruder screw also brings a series of difficulties that need to be overcome: if the residence time of the material in the screw is reduced, it will lead to uneven mixing and plasticization of the material, and excessive shearing of the material may cause the material to rise rapidly and heat up. Decomposition, the difficulty of extrusion stability control will cause the geometric dimensions of the extrudate to fluctuate, the accuracy of related auxiliary devices and control systems must be improved, and the aggravation of the screw and barrel requires the use of highly wear-resistant and ultra-high wear-resistant materials, and reducers How to improve the life of the bearing under the condition of high-speed operation need to be solved.

The high efficiency of high efficiency and multi-functional plastic extruder is mainly reflected in high output, low energy consumption and low manufacturing cost. In terms of function, screw extruder has not only been used for extrusion and mixing of polymer materials, but also has been widely used in food, feed, electrode, explosive, building materials, packaging, pulp, ceramics and other fields. In addition, the "one-step extrusion process" which combines the mixing granulation and extrusion process is also worthy of attention.

Large scale and precision to realize the large-scale extrusion molding equipment can reduce the production cost, which has more obvious advantages in large-scale twin-screw granulation unit, film blowing unit, pipe extrusion unit and so on. And precision can improve the gold content of products, such as multi-layer coextrusion composite film need precision extrusion, and as an important means to achieve precision extrusion, melt gear pump must strengthen the development and research.

Modular and specialized modular production can adapt to the special requirements of different users, shorten the R & D cycle of new products, and strive for greater market share; while specialized production can arrange fixed-point production or even global procurement of each system module of extrusion equipment, which is very beneficial to ensure the whole period quality, reduce costs, and accelerate capital turnover.

Modern electronic and computer control technology has been widely used in extruders in intelligent and networked developed countries. The process parameters of the whole extrusion process, such as melt pressure and temperature, body temperature of each section, rotation speed of main screw and feeding screw, feeding quantity, ratio of various raw materials, current and voltage of the electric machine, are detected on line and controlled by microcomputer closed-loop. Some companies have adopted online remote monitoring, diagnosis and control to control the extrusion line. This is very beneficial to ensure the stability of process conditions and improve the accuracy of products.

Copyright:Zhoushan Tianxiang Screw Factory

China Conical Twin Screws ManufacturersTechnical Support: HWAQ